Finally! The wait for fabric and drapes is over.

First up, the drapes! I bought them from Neutral, an online shop that makes custom sized curtains. I was searching all over for affordable (but not cheap or requiring hemming), aqua-ish, silk drapes. Preferably pinch pleated and 50ish inches wide.

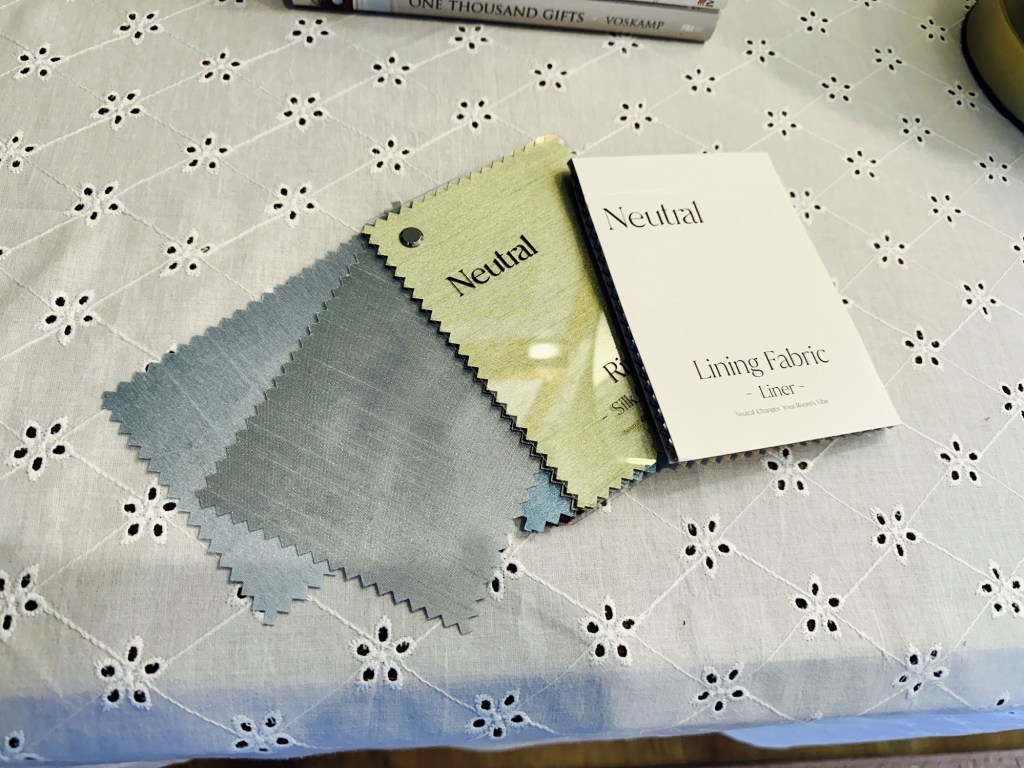

I found the perfect hue in the Rina Premium Silk Drapes in Cyan. I was torn between Cyan and Light Blue, so I ordered samples of both. What arrived was two sample books: one of all the Rina Silk options and one of all their lining options. That made the decisions so much easier! Thanks, Neutral! (Not sponsored, a girl can dream.)

I ordered them on 10/14 and they arrived 10/24. I was concerned due to recent customs issues, but they had no issue making the leap from China to me. They even came with adjustable hangers to hang them on the curtain rings.

Of course, I had to dress them up with this trim from Etsy. Even Austin agrees that the trim was a necessary addition to tie everything together. I sewed them on with just a straight stitch. So far, so good! Then I left them to train after steaming out the creases.

Next up, I ended up ordering the chevron fabric after all, much to Austin’s chagrin… he’s coming around, I promise :).

My original plan was slipcovers, but after several attempts and making 10 yards of piping, I gave up and grabbed my staple gun. All was well until I got to the back and had to reckon with my decisions. Thankfully, I was going to reupholster a different set of chairs once upon a time, and had bought this metal tack strip that saved the day. Thanks, past self. I love when that happens.

When Austin got home, we worked on the back, and wouldn’t you believe that it actually worked?! I wish I could say I was less surprised but wow, could it all really be so easy? Ask me again in a year for how they’ve held up.

Whew, y’all. I can see the finish line. It’s still past five chairs, but it’s there. With three week until Thanksgiving. Tender mercies.

I’ll keep you posted!

xo, Amanda